Product Description

HydroSystem 1000 Roof is a SUDS Multi-process Treatment Device for use in SUDS Treatment trains. It is designed for installation to treat roof run off for roofs without a significant proportion of uncoated bare metals (<50m²). HydroSystem 1000 Traffic and 1000 Heavy Traffic versions are also available for trafficked areas. This is an upflow filter, removing dissolved contaminants, as well as suspended sediments. Unlike all down flow filters, it will not block after a few weeks of use. Filters 100% to 70 microns.

The HydroSystem 1000 Roof is a multi-process SUDS stormwater treatment device, with four stormwater treatment stages. Recommended connectable surface area of 1000m2 depending on contamination loading from the runoff. Extendable connected area, after SUDS flow control devices.

Fully DIBt Approved and certified for 92% TSS removal. Fully NJDEP approved for online positioning at 80% TSS removal. This device is referenced in the CIRIA SuDS manual (see Chapter 14 Part D: Technical Detail, and Chapter 26, Part E: Supporting Guidance), as a multi process, multi stage treatment process device.

For installation within standard DN1000 chambers of concrete and PE. Can be provided in "plug and play" configuration in PE chamber.

3P Hydrosystem products are designed and certified to perform and prevent damage to fragile and important ecosystems. They remove a wide range of contaminants from water including Polycyclic Aromatic Hydrocarbons (PAHs) and dissolved heavy metals such as zinc and copper.

The cleaned water has such an excellent water quality that it can be discharged directly into soakaways, infiltration cells and even ddirectly to surface waters and the wider water environment.

The 3P Hydrosystem 1000 Filter uses an up-flow process. This means there is a minimal head drop across the inlet to outlet. There is no chance of filter clogging, unlike all downflow type filters. Minimal chance of filter clogging.

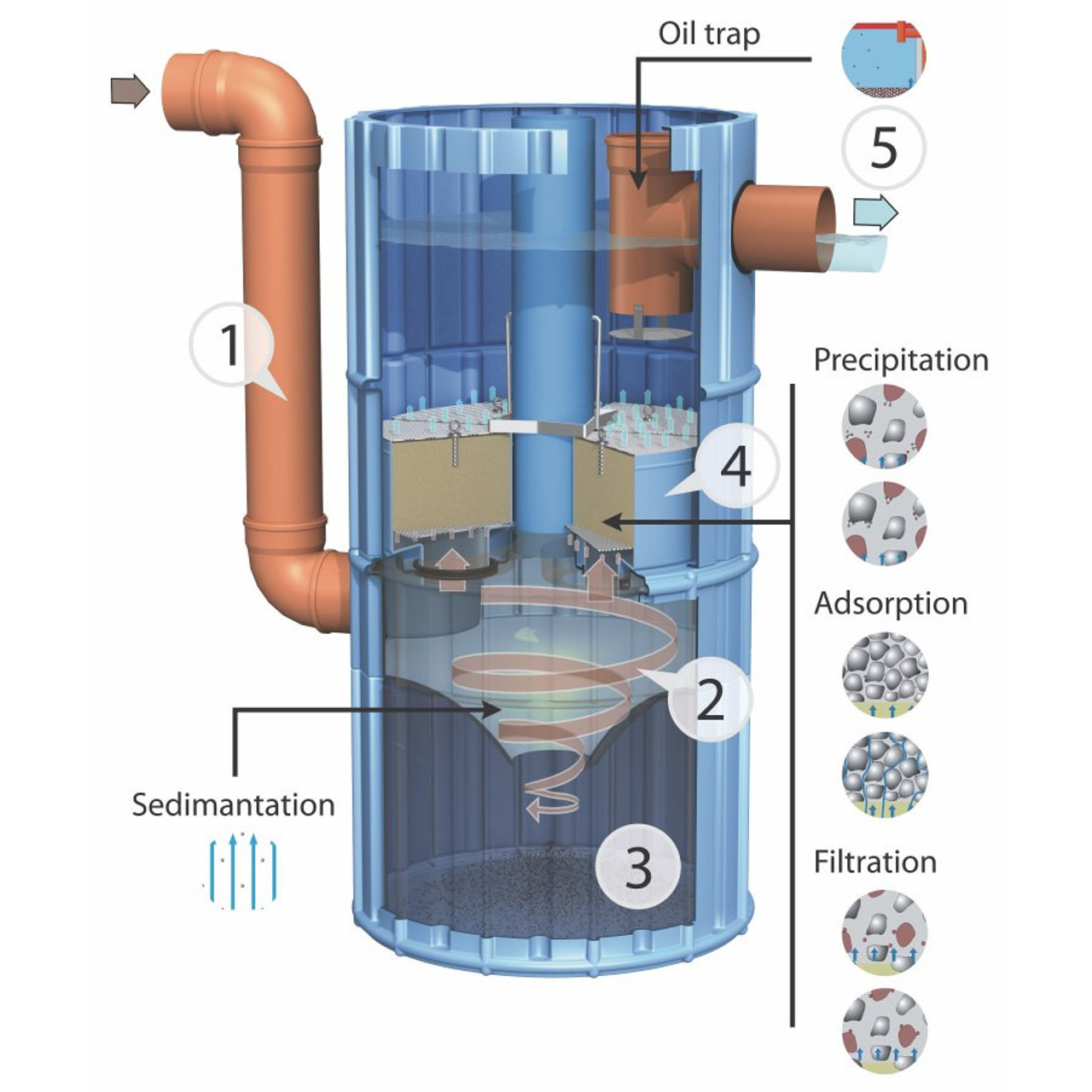

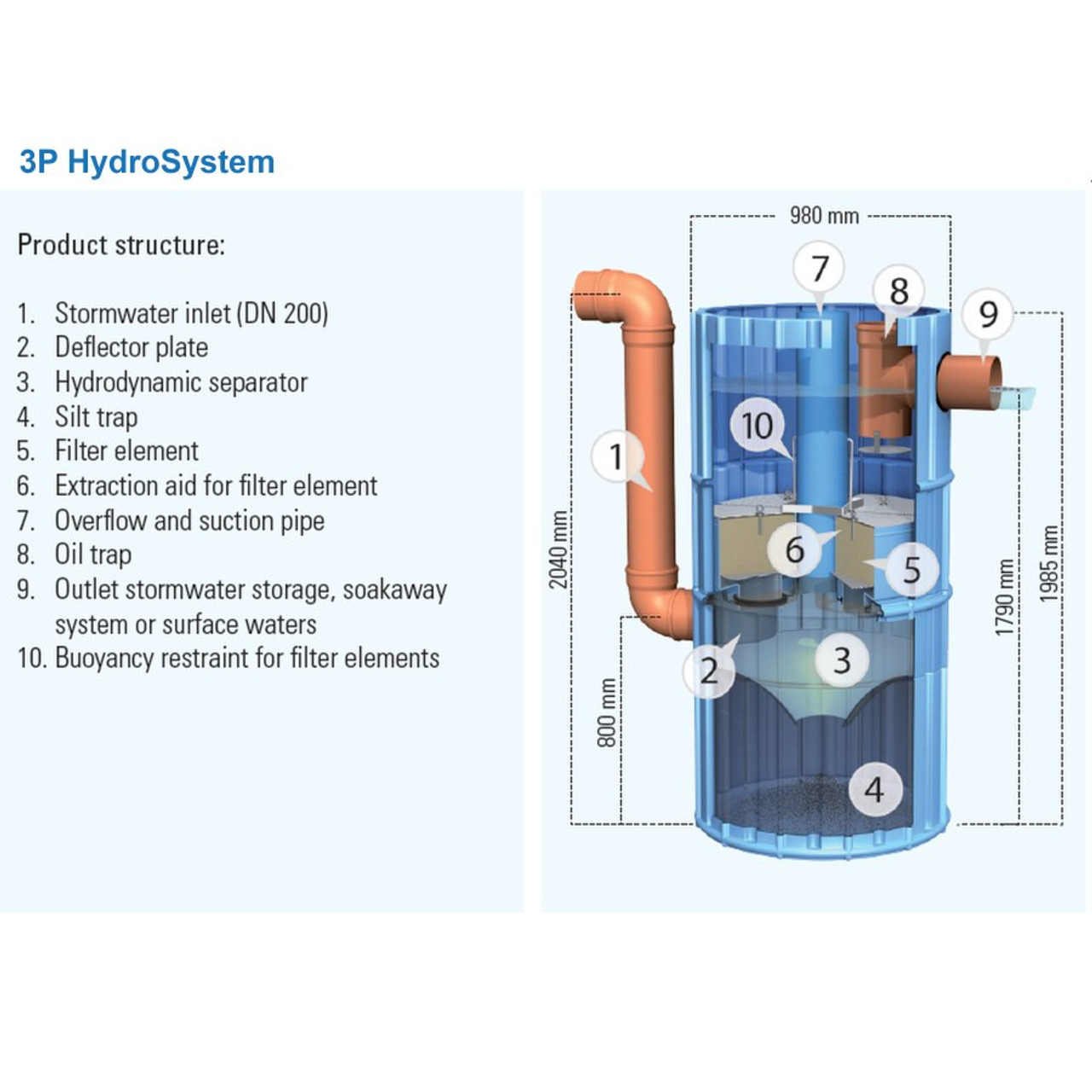

The rainwater is treated within the Unit by the following processes: sedimentation, filtration, adsorption and precipitation.

The first treatment step takes place in the Hydro Dynamic Separator, where sedimentation of solid particles occurs within a radial flow regime, characterised by secondary flows. A settling funnel to the silt trap chamber entrance ensures sediments are not re-mobilised. this is simialr to the basic Vortex Separators used in the UK market to remove up to 50% of TSS.

Above the vortex separator are the filter inserts, which cover the entire diameter of the unit’s housing. Water flows upwards through the removable filter elements. As a result of the upward flow of the filter element, and that the filter remains saturated, filter clogging by solids is very limited and slow.

Where To Use The Hydrosystem 1000 Roof

The EU, USA and UK standards require runoff from highways, busy car parks and industrial areas to remove a wide range of contaminants, including PAHs, phosphate, ammonium and and heavy metals such as zinc and copper. Removing solids alone will typically be insufficient to properly treat stormwater.

This Roof version is designed for installation to treat roof run off for roofs without a significant proportion of uncoated bare metals (<50m²).

All 3P Hydrosystem products are designed and certified to perform and prevent damage to fragile and important ecosystems. These units pass the DiBT standard, as referenced in the CIRIA SuDS manual (see Ch 14 Part D: Technical Detail, and Ch 26, Part E: Supporting Guidance) and meet performance standards that are understood and accepted by the Environment Agency in England, NRW in Wales and SEPA in Scotland.

3P Hydrosystems are particularly relevant for polluted water treatment draining trafficked roads in sensitive catchment areas, groundwater zones and Sites of Special Scientific Interest (SSSIs). They support effective Stormwater Pollution Prevention Plans (SWPPP) and can be part of Stormwater Best Management Practices (BMP) along with Water Sensitive Urban Design systems. They perform to tight independently certified international standards that are imposed on runoff to protect both surface waters and groundwaters alike.

How it works

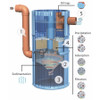

(see also numbered diagram above)

Multi-process SUDS Treatment Device Stages

- The stormwater from the connected area is fed into the inlet, at the lower end of the shaft. A deflector plate sets up a radial/vortex flow.

- Sedimentation of particles, especially of the silt and sand faction takes place in the hydrodynamic particle separator. This is due to turbulent secondary flows within a radial laminar flow regime. Vortex separation, proven water treatment technology.

- The settled solids are fully retained (DiBT proven). They are evacuated via the central by-pass tube periodically at site specific intervals.

- Four multi-process filter elements are located within the HydroSystem filtration stage. As the waters flow upwards the finer particles are filtered out, whilst the dissolved pollutants are precipitated and absorbed. The multi-process filter is easily back-washed, and if completely clogged or exhausted, is easily replaced. Metals once bound cannot be remobilised from the filters by road salts in the incoming stormwater, DiBT proven.

- Clean water above the filter elements passes to discharge via an oil trap/floatables assembly. Normal concentrations of dissolved oils are fully retained within the filter elements. Discharged to ground or surface waters in a SUDS system or other green infrastructure.

Maintenance

No moving parts. The filter cartridges are easily changed once exhausted (approximately every 3 to 5 years). The system is maintained and can be back flushed once a year where required without filter removal.

Cleaning of systems and replacement cartridges can be arranged through Rainwater Tank Cleaning Ltd.

Technical Information

- Rainwater filter complying with DIN 1989-2, Typ A;

- Connections: DN 200

- Outside Diameter of the system chamber : 998mm (fits in 1000mm chamber)

- Minimum head loss between inlet and outlet: 250mm

- Connectable area: to 1000m2 dependent on site conditions and design parameters

- Maximum flow rate: *l/s

- Maximum Filterable flowrate: 12l/s

- Treatment flowrate: *l/s

- Housing material: Polyethylene

- Weight of Housing: 68 kg approx

- Weight of each filter : 34kg each (4 in each housing).

* Please contact us to discuss flow rates and your preferred design definitions around flow rates.